Shop by Category

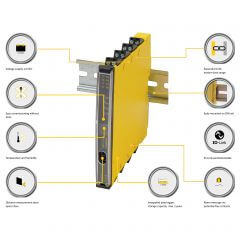

Turck IM12-CCM Cabinet Condition Monitor

Cabinet Condition Monitor with internal data logger and IO-Link interface

Features

The IM12-CCM features an internal data logger with time stamp and stores data for up to two years, allowing users to detect creeping changes over long periods of time. An interface enables two cabinet guards to be operated in master-slave mode simultaneously, monitoring correct door closing and other limit values at two points within the control cabinet. The master processes the data of the slave and sends a signal to the controller.

The standard IM12-CCM comes with two switch contacts and an IO-Link interface. Quick teach mode enables the user to set the limit values easily in the field. Alternatively, parameters can be set via IO-Link or an FDT framework such as PACTware.

The IM12-CCM is the second cabinet guard in the Turck portfolio, serving as a supplement to the IMX12-CCM module, which is intended for use in hazardous areas.

Detecting Gradual Changes

Humidity is often a problem in enclosed systems and should, therefore, be measured continuously as part of the condition monitoring system. The protection provided by control cabinets can decrease as the period of operation or the load increases. This can either be due to mechanical damage, the aging of the sealing material, defective ventilation systems or negligence such as incorrect closure. It is often gradual processes, such as continuously increasing humidity, that eventually lead to the failure of installed equipment. These effects can often only be detected over a long period. Turck’s control cabinet guards also detect these long-term trends and notify the control level when limit values are exceeded.

.png)

.png)