Shop by Category

Omron ZW-5000 Compact Confocal Sensor

Solve more inspection applications

The ZW-5000 outperforms laser displacement sensors in inspection applications where its ultra-small spot size makes it possible to do high-precision gap, position and profile measurements. Sensors with larger beams can be an effective solution for profile inspection where rough surfaces produce unwanted measurement results. Their large spot size helps ignore the roughness by averaging heights within the sensing area.

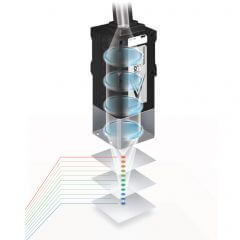

Proven technique for profiling

Pioneered over 20 years ago in Omron’s Automated Optical Inspection (AOI) machines, the height of micro components and solder beds are measured based on the color of the returned light. The ZW-5000’s coaxial illumination provides precise measurements of the returned light wavelengths from the object through the same optical path. This capability is housed in a compact, industrially hardened, sensor head and easy to integrate system.

White light vs. laser

It comes down to safety and installation space. Most sensors used in these applications are equipped with a laser light source that requires physical safeguarding, which may pose a problem within confined spaces in today’s production lines. The ZW-5000 confocal sensor uses a white LED light source to eliminate the issues that arise when utilizing a laser.

Accurate for inclined and curved surfaces

Laser triangulation methods are not suitable and provide erratic measurement results when applied to inclined and curved surfaces. The ZW-5000 can handle inclined surfaces with its ability measure surfaces at ±25°. The confocal light successfully measures features with a high aspect ratio, such as objects in narrow diameter vessels. The outgoing light returns along the same optical path as the light reflected back from the object’s surface.

Non-contact, confocal, white led displacement sensor

Strict quality control, production speed, and appearance inspection are constantly increasing. To meet these demands, stable measurements during movement for quality inspection without compromising manufacturing speed are required.

Harnessing the benefits of the white light confocal principle, the ZW-5000 meets these demands for most any material type including glass, metal, plastic, and so on, and shapes such as round, flat, uneven, etc.

ZW-5000 Product Benefits

Small spot diameter down to 9µm improving the ability to measure minute profiles

Constant spot diameter throughout total measuring range

Slim form factor of the optical probe – fits anywhere

Response time as fast as 20µs – Enables high-speed sampling during motion

High Resolution of 0.25µm allows hairline pattern measurements or irregular surfaces

Linearity down to ±0.45µm regardless of material type, as a result, no tuning is required

Superb angle compensation of ±25° makes the measurement of round or inclined surfaces possible

Machine control integration made easy with available DLL files

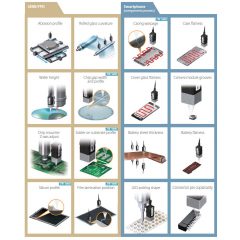

Applications

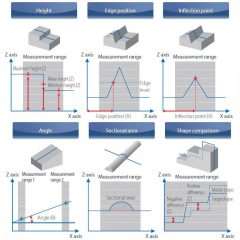

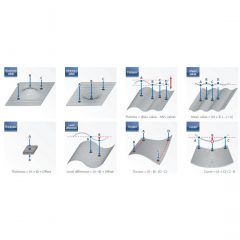

The ZW-5000 confocal sensor uses function blocks within Sysmac Studio software to implement many types of measurements. For instance, the ability to combine data points from multiple sensors or extracting 2D profiles. A full inspection system configuration includes an NJ, NX controller or NY IPC running Sysmac Studio.

.png)

.png)