Shop by Category

Omron E2E NEXT Proximity Sensors

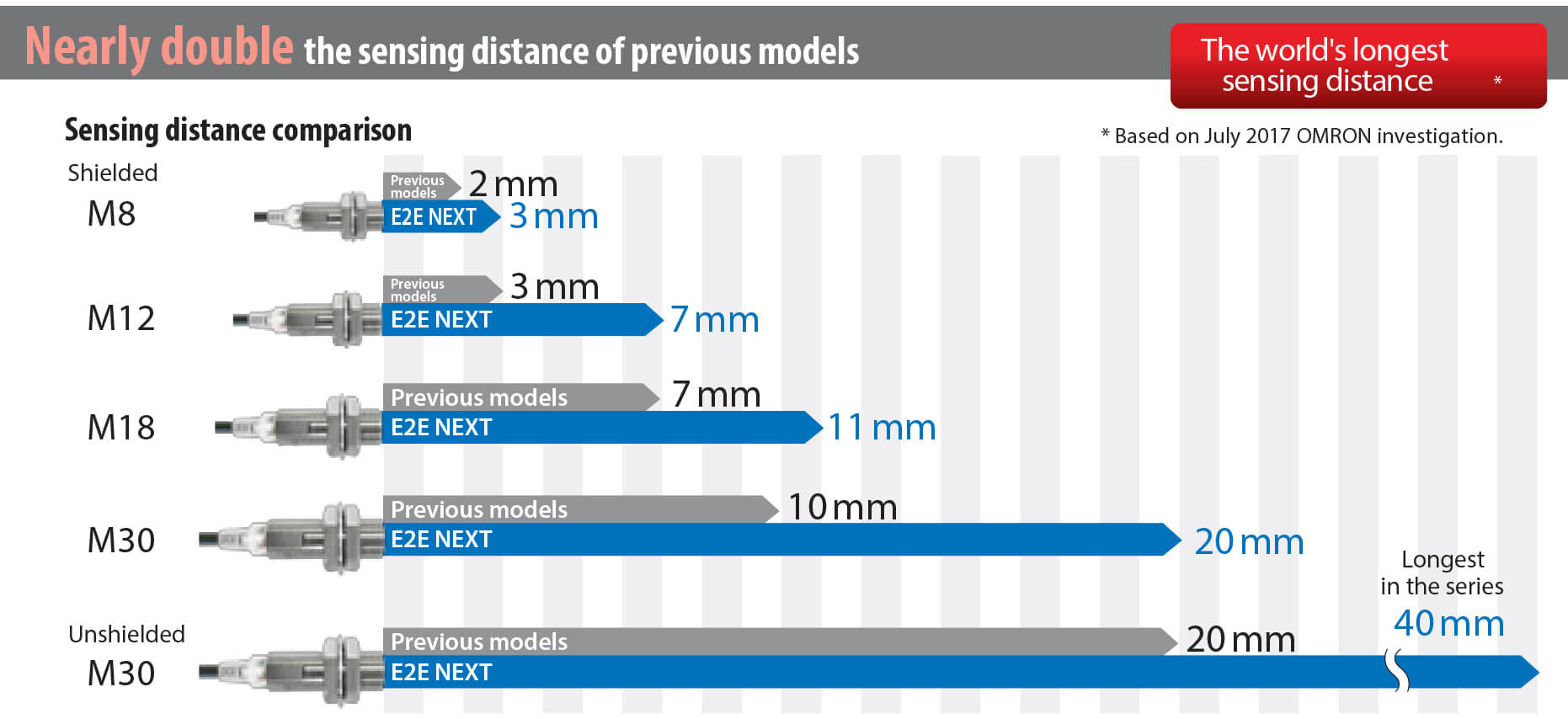

Long-distance detection prevents unexpected facility stoppages

New E2E NEXT Proximity Sensors reduce unexpected facility stoppages due to false detection, failures, and damage caused by previous proximity sensors.

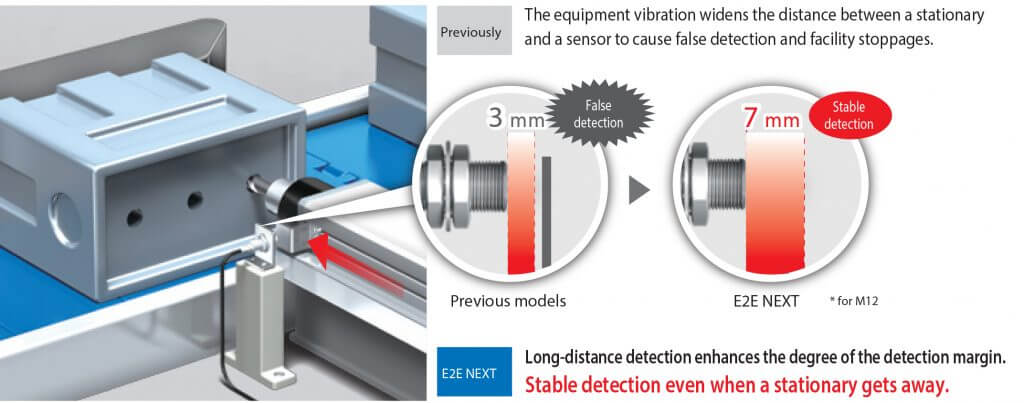

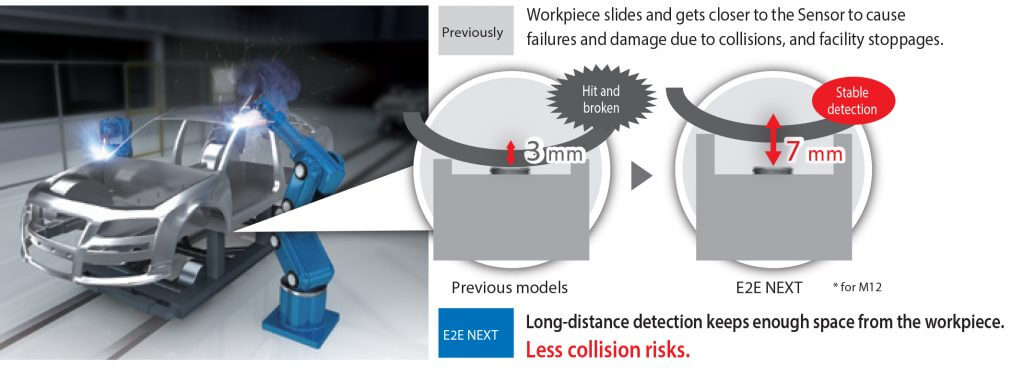

Where the previous M12 model had only 3mm of sensing distance, the new E2E NEXT M12 model has 7mm of sensing distance.

They enhance stability

The E2E NEXT line’s long sensing distance prevents unexpected equipment downtime caused by contact, making the overall application more stable.

They promote flexibility

The extra-long sensing distance makes it possible to address size-limited applications with smaller form factor sensors.

They enable IIoT applications

The DC 3-wire models use IO-Link to help identify the location and nature of failures in real time.

They reduce failures

E2E sensors are resistant to cutting oil, which accounts for approximately 30% of unexpected component failures.

They improve recovery times

The sensors’ user-friendly design makes it easy to confirm detection status and ensures that your equipment can recover quickly without requiring advanced support.

Less false detection even when a stationary gets away from the sensor due to equipment vibration

When workpiece sitting position varies or it has deflection, collisions are unlikely to happen

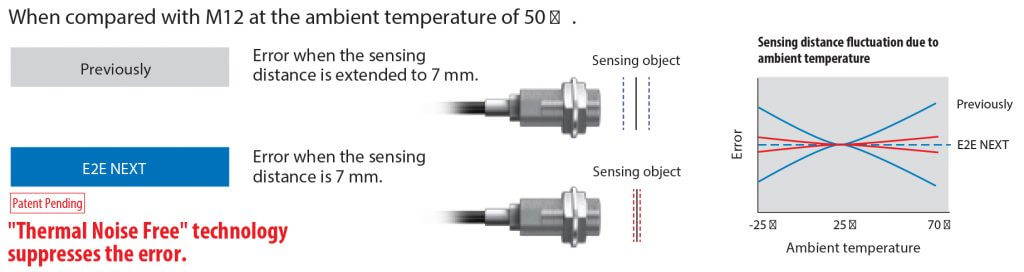

"Thermal noise free" technology that enables long-distance detection

When you tried to increase the sensing distance of proximity sensors by conventional technologies, the change of ambient temperature greatly influenced and it was impossible to use those sensors at actual production sites. The newly developed technology by OMRON, “Thermal Noise Free” technology, minimizes the characteristics change due to temperature by high-precision compensation and enables long-distance detection.

Enhanced usability enables facilities that can recover in a short time without skill requirements

Less time required from failure to recovery (MTTR: Mean Time To Recovery).

Only 10 Seconds * to Replace a Proximity Sensor with “e-jig”.

E2E NEXT contains components that shut out cutting oil for 2 years further reduced unexpected facility stoppages

The Sensor reduces further unexpected failures in environments requiring oil resistance in addition to damage caused by collisions

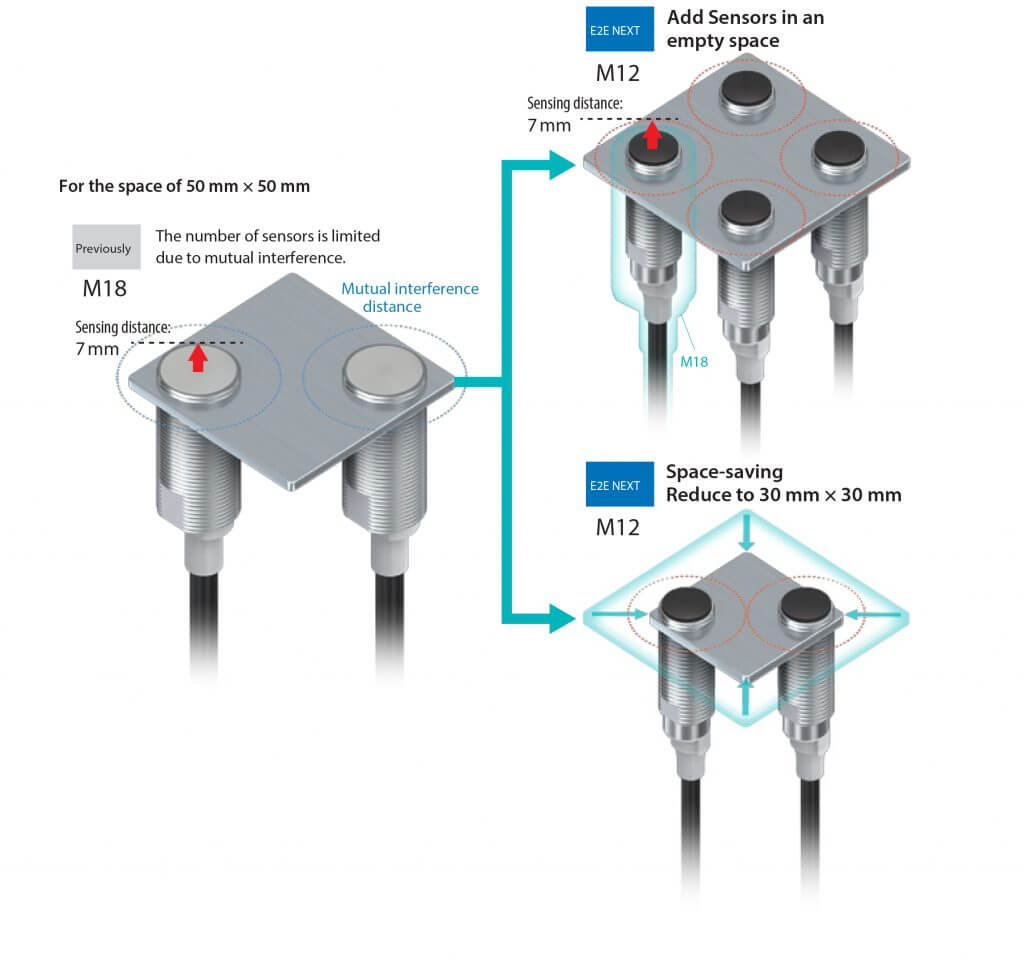

Downsized sensor enhances flexibility in facility design

Longer sensing distance enables one size smaller sensor with the same sensing distance, so we can add more sensors to an empty space and save space for the installation.

Models are available in both DC 2-wire and DC 3-wire

DC 2-wire Features:

Up to double the sensing distance of previous E2E models

1x and 3x sensing distances available across the size range

Enhanced sensing distances reduce contact with targets

Pre-wired & pre-wired connector models: IP67; IP67G; IP69K

UL (UL60947-5-2), CSA (CAS C22.2 UL60947-5-2-14), CE

360° visible output indicator

Easily installed with Quick Fix

DC 3-wire Features:

Up to four times the sensing range of standard models

Enhanced sensing distances that reduce contact with targets and improve longevity

1x, 2x, 3x, and 4x sensing distances available across the entire size range

IO-Link offered with NO,PNP and NONC,PNP models

Pre-wired & pre-wired connector models: IP67; IP67G; IP69K

Connector models: IP67; IP69K

UL (UL60947-5-2), CSA (CAS C22.2 UL60947-5-2-14), CE

360° visible output indicator

Easily installed with Quick Fix

.png)

.png)