Shop by Category

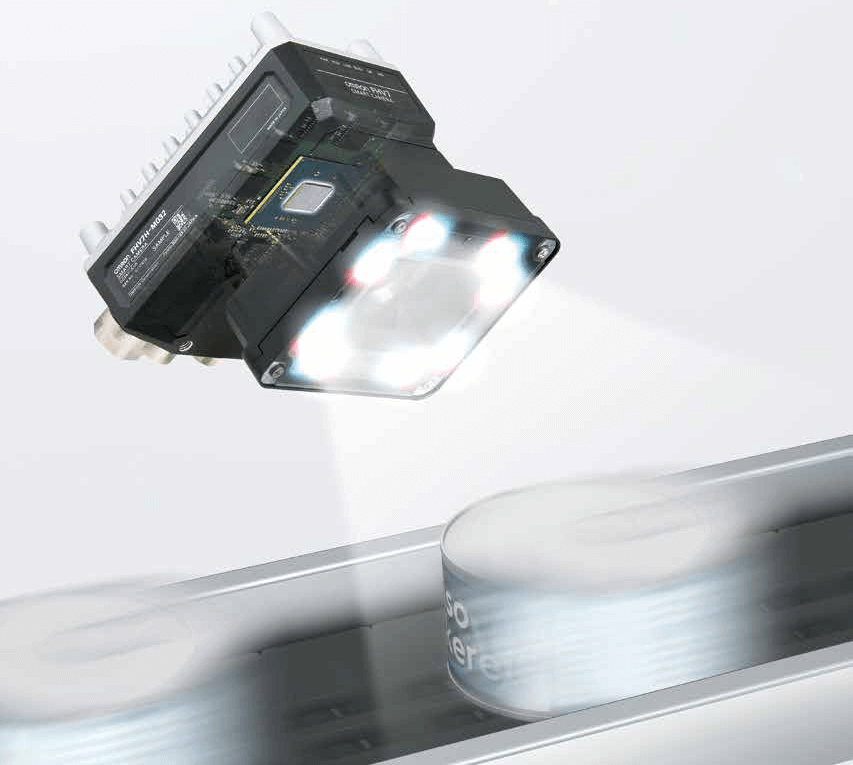

Omron FHV7 Series - Smart Camera

New FH AI-based defect detection exceeds the ability of expert inspectors

Artificial intelligence has reached the stage where it can recognize object features as well as humans and automatically learn criteria. While a lot of AI solutions face challenges with large amounts of image data, specialized hardware, and engineering expertise, Omron is making great progress in enabling its widespread use with the New FH AI system.

Learn More

Omron's comprehensive brochure includes the highly detailed information you need to review when making your decision to consider this new AI defect detection series. Download brochure.

New FHV7 Series Smart Camera maximizes precision in high mix production line inspections.

Omron's new FHV7-series smart camera features the world's first multi-color light alongside a best-in-class 12-megapixel high-resolution image sensor to achieve the industry's highest standards of precision in vision inspections on a high-mix production line.

Multi-color light that automatically changes the lighting to accommodate product modifications and new designs

A range of sensors from 0.4MP up to 5MP, with versions up to 12MP available in the near future to enable high-precision inspections for wider areas and eliminate the need for installing multiple cameras or a mechanism to move a camera to capture different inspection points on different products on the same line

An auto-focus lens that covers a focal distance between 59 and 2,000 mm, ensuring that even when differently sized products are created, the focal range can be changed easily by altering parameters rather than by moving the camera

Industrial ruggedness through an IP67 design that ensures vibration and shock resistance

Dual-core CPU that provides the fastest image processing speed among smart cameras (four times faster than the previous generation)

High-speed image logging that enables an inspection to be conducted while image data is being saved

High-speed image data compression that facilitates data storage enabling complete traceability

Highly configurable offering with a variety of optics and lighting options

Automation-ready connectivity with EtherNet/IP and PROFINET support as well as direct integration with and camera configuration via Sysmac Studio

Full range of accessories that includes several optical filters, protection hoods, and cables

Powerful vision software that builds off of the proven FH series of image processing and inspection features

A smart camera that promotes flexibility and traceability

The FHV7 promotes easy integration of vision inspection into flexible manufacturing processes. Equipped with a multi-color light and an autofocus lens, it can respond flexibly to changes in the color and size of objects to be inspected, eliminating the need for special camera installation and adjustment skills.

The smart camera’s high-speed image compression algorithm works at double the regular speed, enabling all image data to be saved even during measurement tasks and allowing complete traceability in production processes where quality control is paramount.

Applications

Automotive parts inspection

High-speed food & beverage or consumer product goods product inspections

Electronics PCB and higher level assembly inspection

Pharmaceutical products and packaging

General manufacturing

.png)

.png)