Shop by Category

Automotive Solutions from Panasonic

Looking for automotive solutions?

Looking for automotive automation solutions? Below are some selected examples of Panasonic has products engineered for automotive assembly. Don't see what you're looking for? Give us a call at 1-800-280-6933 and we can help you with your application needs.

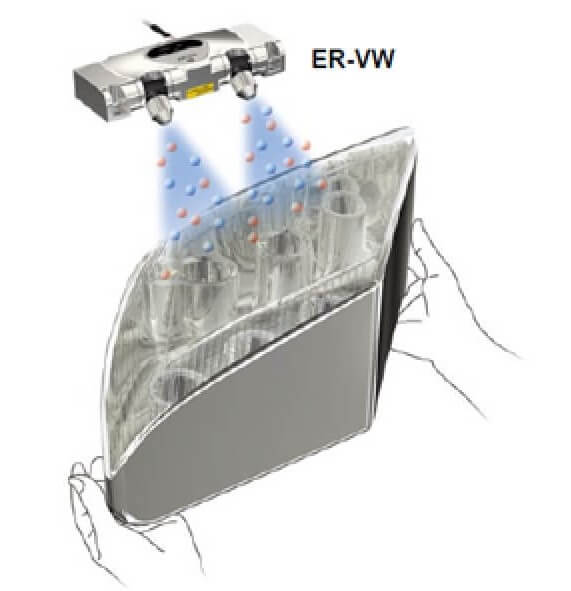

Dust removal during light cover assembly

The main body of the ER-VW is 18.9 mm (0.744 in) thick and since the nozzle angle can be adjusted, the ionizer can be used even when space is limited.

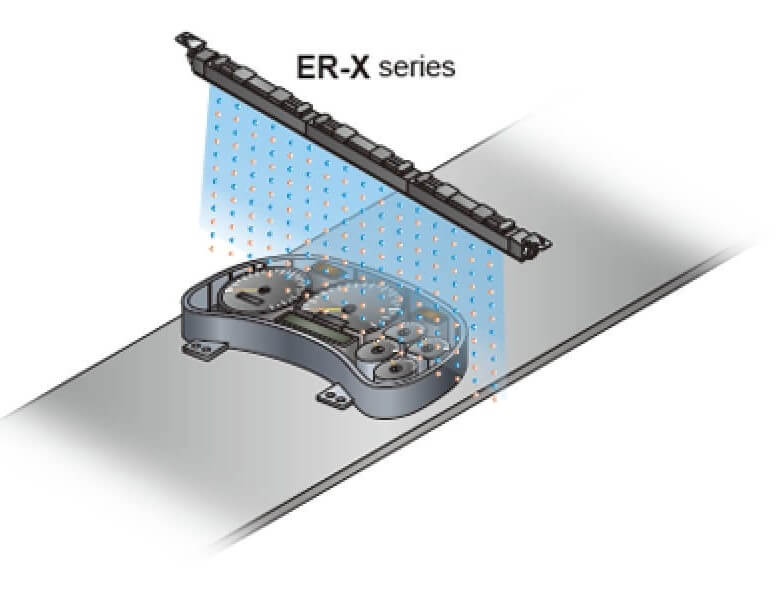

Removing dust during instrument panel assembly

If dust adheres to an automobile instrument panel, it may cause a quality defect. The ER-X series, which can perform high-speed charge removal without stirring up dust, is ideal for use in preventing contamination and dust adhesion.

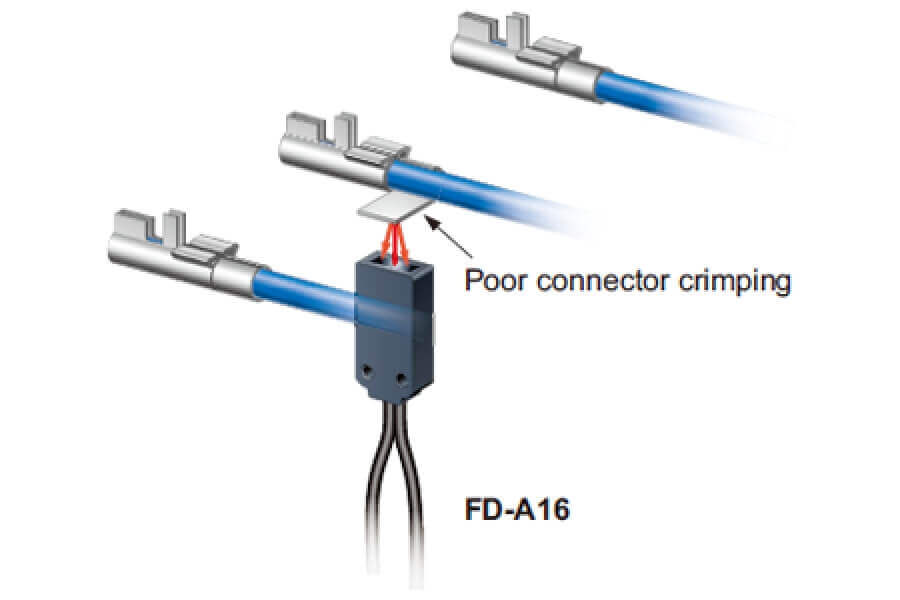

Detection of defective connectors

The FD-A16 has a rectangular spot with a large beam area. Since the light receiving parts are on the upper and lower positions of the light emitting part, stable detection is possible even if connector positions are a little off.

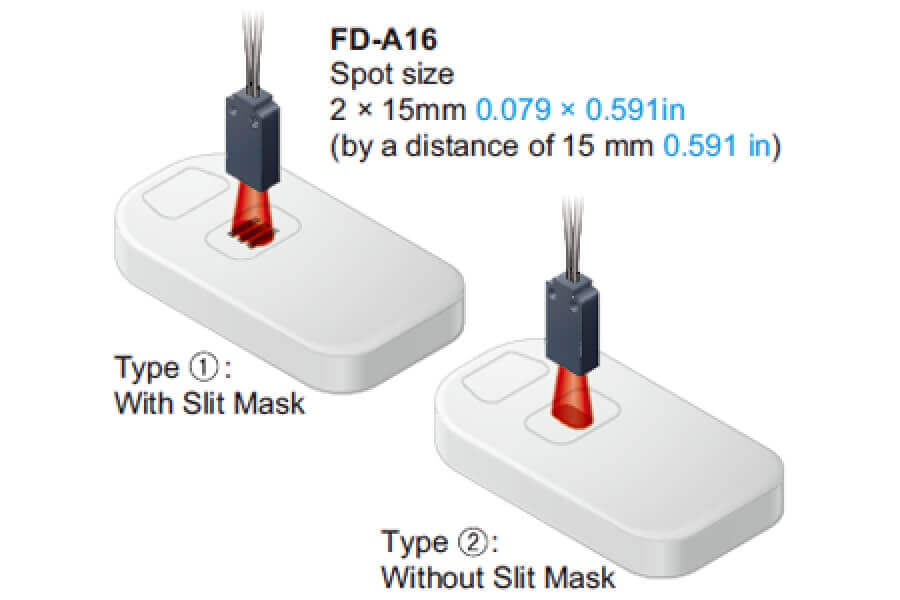

Distinguishing differences in parts

The fiber sensor distinguishes the model of overhead consoles for automobiles by differences in shape (presence of slit mask). Since it performs sensing by beam area using wide beam fibers, it can distinguish the model through differences in reflected beam intensity.

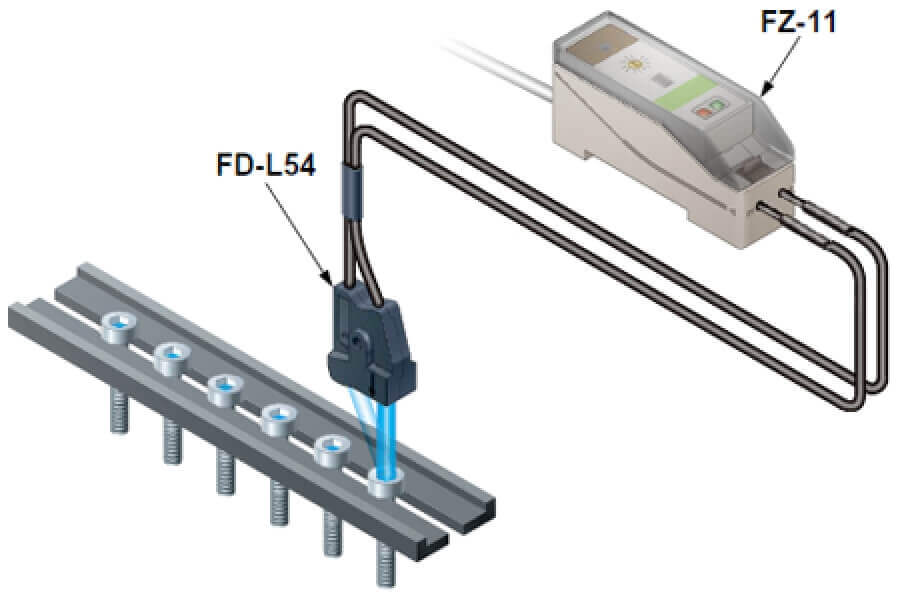

Color mark detection of screw heads

The FZ-10 can make extremely accurate color distinctions because it digitally distinguishes each color component (red, green, blue).

Safeguard robotic assembly areas

The SF4D series that complies with international safety standards has a built-in muting control function, contributing to safety, productivity, and cost reduction.

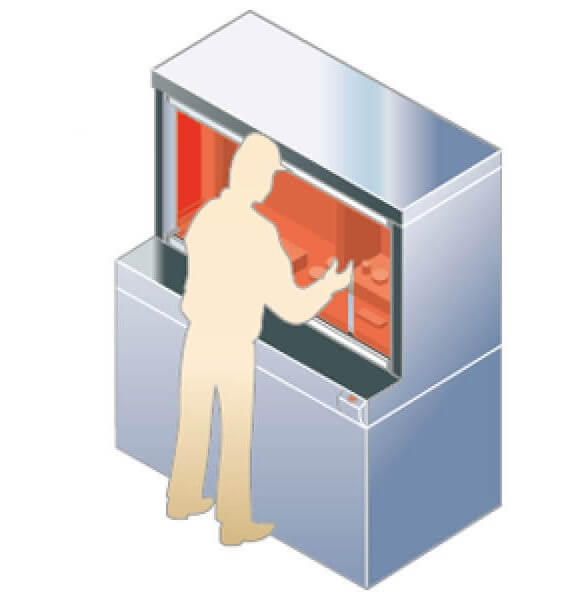

Machine safeguard

The operator has to access the special purpose machine to change the work pieces. The light curtain maintains a high level of safety without decreasing the productivity.

.png)

.png)