Shop by Category

Packaging Solutions from Panasonic

Looking for packaging solutions?

Check out some selected possible applications of Panasonic products engineered to improve your packaging processes. Don't see what you're looking for? Give us a call and we can help you with your application needs. 800-280-6933.

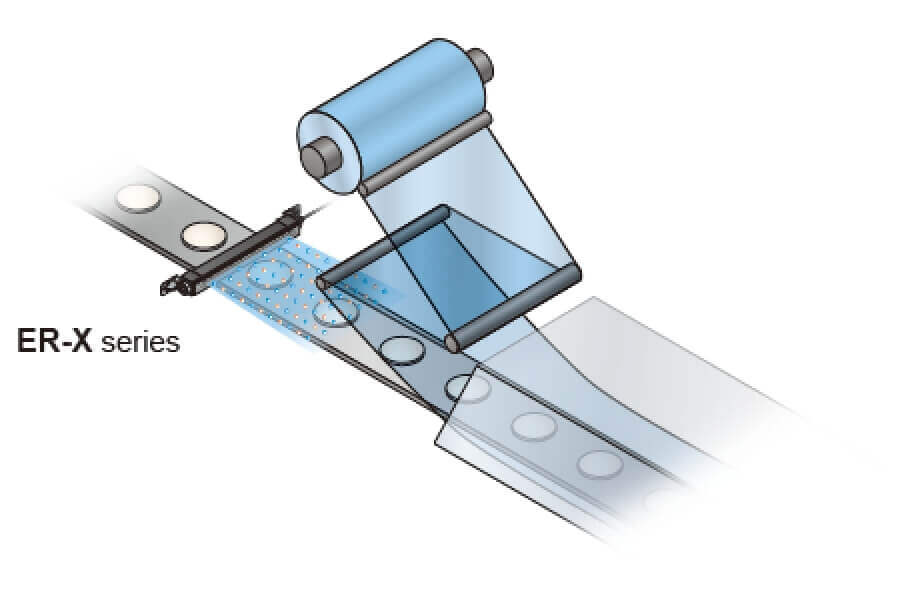

Prevent jamming of packaging materials

It is recommended to prevent adhesion of contamination and dust, which can cause process defects, with the ER-X series, which provides airless, high-speed charge removal capability.

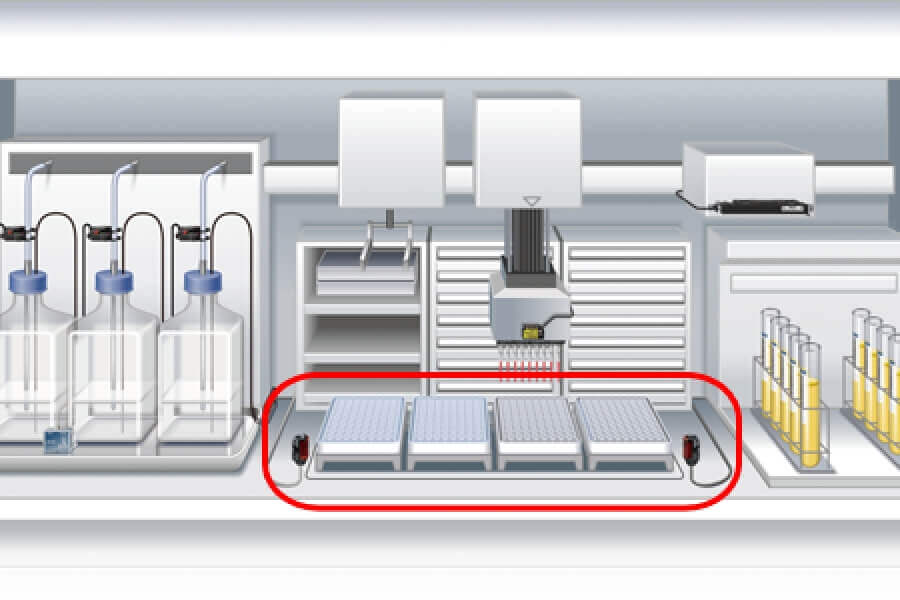

Work positioning

Ideal for positioning microplates, the distinctive features of the EX-L200 lasers include their high degree of directionality and visibility. Ultra-compact in size, yet provides high-precision detection performance.

Cleaning bottles

Contamination inside bottles that will be used to hold medicines or cosmetics can have a significant negative effect on the quality of the product. The ER-VS02 can be used to eliminate static electricity inside the bottle by means of nozzle transport and prevent re-adhesion of the contamination.

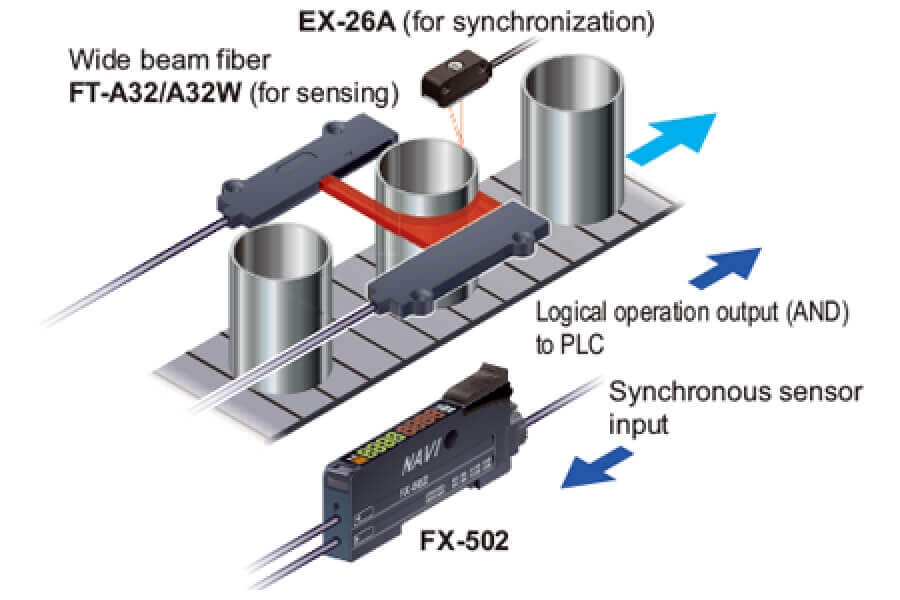

Distinguishing types of containers

By using a wide beam fiber, stable sensing is possible because the incident light intensity varies according to differences in container size. FX-502 can make model distinctions using fewer sensor units and I/O points than that of a conventional setup by using external input and logical operation output and making distinctions by window comparator mode. This contributes to total cost reduction.

.png)

.png)