Shop by Category

Grace Engineered Voltage Test Station

Enhance your electrical safety program through safety-by-design

The Voltage Test Station combines Grace’s Safe-Test Point with a voltage indicator conveniently placed within a protective housing. The VTS test point jacks allow measurement of AC/DC voltages either phase to phase or phase to ground. The R-3W Series voltage indicators with either flashing or non-flashing LEDs visually represent the presence of voltage

Features

- The Voltage Test Station (VTS) is a Permanent Electrical Safety Device (PESD) that allows workers a safer way to verify presence or absence of voltage from outside the electrical cabinet.

- The VTS combines Grace’s Safe-Test Point with a voltage indicator place inside a protective housing. It can be hardwired directly to energy sources and allows visual verification and measurement of AC/DC voltages through a meter test.

- It provides a safer and more productive method of performing Lockout/Tagout (LOTO) while exceeding NFPA 70E standards and meeting the OSHA energy isolation principle.

- Various lockable housing options add additional layers of protection and allow authorized personnel to conveniently access the VTS.

Voltage Test Station Operation

Following facility safety procedures, insert the insulated meter probes with 0.08? tips into any two test point jacks to take a voltage reading with properly rated test equipment.

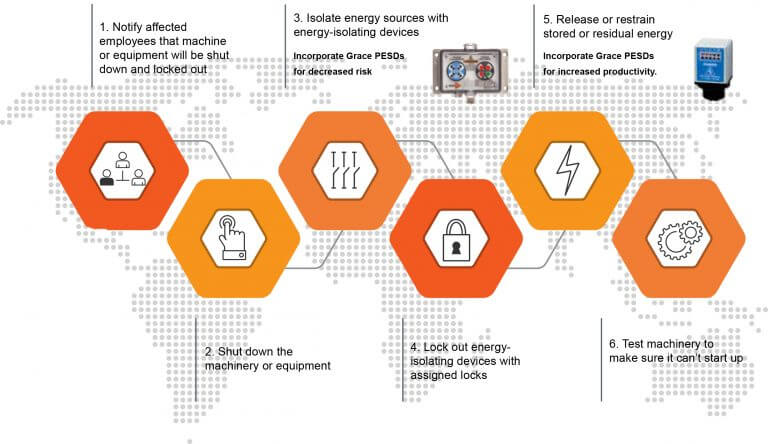

Step 1: Notify affected employees that machine or equipment will be shut down and locked out.

Step 2: Shut down the machinery or equipment

Step 3: Isolate energy sources with energy-isolating devices. Incorporate Grace PESDs for decreased risk

Step 4: Lockout energy-isolating devices with assigned locks

Step 5: Release or restrain stored or residual energy. Incorporate Grace PESDs for increased productivity.

Step 6: Test machinery to make sure it can’t start up

Why should you go beyond compliance with Grace PESDs?

Voltage is the common denominator in an electrical accident or an arc flash; no voltage means no accident/arc flash. At Grace, our mission has always been to ensure that every electrical worker returns home safely to their family and loved ones. With electrical safety meshed in our DNA and programmed in our brains, we are always striving for ways to improve the workplace electrical safety standards by developing innovative products and solutions that minimize the risk of electrical exposure. PESDs are a result of a constant zeal to find simple, innovative and practical ways of developing electrically safer work conditions that reduce accidents, improve productivity, enhance compliance as well as foster a safety culture.

.png)

.png)