Shop by Category

Omron NX1 Series Machine Automation Controller

Faster production without having to compromise on quality

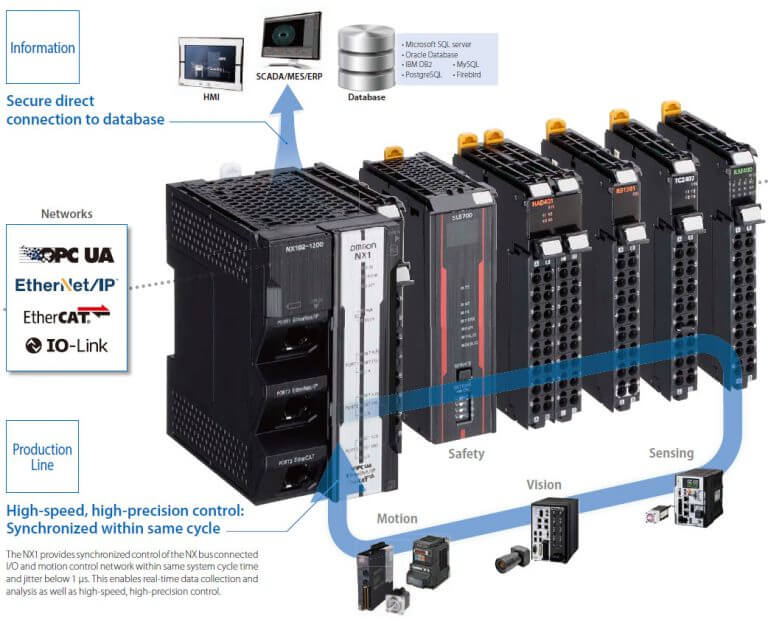

The NX1 can utilize information, take safety measures, and control quality while at the same time improving production efficiency through high-speed, high-precision control for continuous improvement in productivity.

Real-time traceability with the NX1

The NX1 provides high-speed control while utilizing information. For example, the NX1 used for a packaging machine with the capability of handling 1,000 products per minute can collect all traceability data in synchronization with the production cycle while performing motion control.

Integrated safety across the production line

The NX1 is the first in the world* to integrate two different open networks: EtherNet/IP™ for scalable safety control in production lines and EtherCAT® for fast safety control in machines. Furthermore, it integrates safety control into machine control in lines that require fast cycle times. This integration allows you to standardize machines and build flexible lines.

* Based on Omron investigation in March 2018.

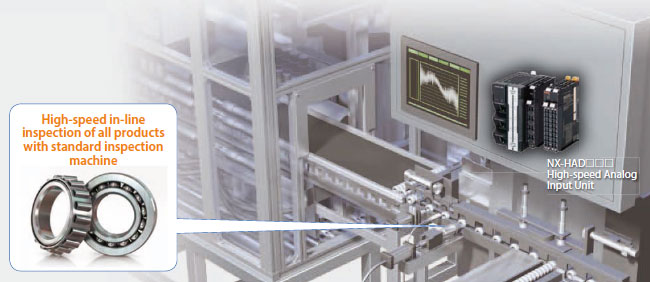

High-speed in-line inspection with the NX1

Although special inspection machines with built-in PC are widely used for high-speed inspections, they require special maintenance skills. Therefore, acceptance sampling is often carried out offline to prevent line stoppages.

The NX1 can be used in conjunction with the High-speed Analog Input Unit to collect measurement data within a fixed cycle time of 5 µs. This standard controller eliminates the need for special machines with PC and can be maintained by on-site engineers. Inline inspections of all products can also be conducted easily.

Seamless integration: production line & IT systems

The NX1 Controller integrates inputs, logic, outputs, safety, and robotics, offering a wide variety of applications that leverage information to boost productivity and measures for quality and safety.

NX1 brings advanced control in miniature size

Three industrial Ethernet ports and a power supply are housed in a compact design with a width of 66 mm. The NX1 provides key functionality to integrate control and information for advanced manufacturing applications. The new controller contributes to the pursuit of productivity improvements.

High-speed, high-precision control

Synchronized control of I/O and motion within 1 ms cycle time Jitter: 1 µs Memory capacity for variables: 33.5 MB*1

Secure host connection

OPC UA is an IEC communication protocol which is listed as a recommendation for Industrie 4.0 and PackML. The NX1 comes equipped with an OPC UA server interface and provides a secure connection to IT systems such as MES and ERP.

Enhanced Ethernet functionality

Connectivity to existing devices (e.g., Modbus/TCP*2, FINS communications, and connection to other vendor PLC*3) and EtherNet/IP™ performance (increased to 12,000 pps*4) are improved. Packet Filter enhances security, and visualization of EtherCAT® slave errors makes troubleshooting easier.

A multicore microprocessor for control and data handling

The multicore microprocessor enables information utilization including communications and traceability without compromising control performance.

*1. The total number of bytes of retained and non-retained variables.

*2. Clients instructions are supported.

*3. SLMP commands are included in the Sysmac Library.

*4. The total pps of two ports.

.png)

.png)