Automotive Solutions

Engineered Recommendation

Ramco's automotive solutions manage dust; light-guided assembly; automotive traceability and black part detection on black door panels and more.

Product Selection & Delivery

Ramco Innovations has over 50 years of experience in distribution and logistics, assuring on-time delivery, excellent communication for project planning and quick turnaround on consumables.

On-Going Support

Ramco Innovations has a team of in-house experts at the ready to respond to your needs. Contact us to speak to one of our experts using our contact form, the chat function below or call 800.328.6236.

Dust Management

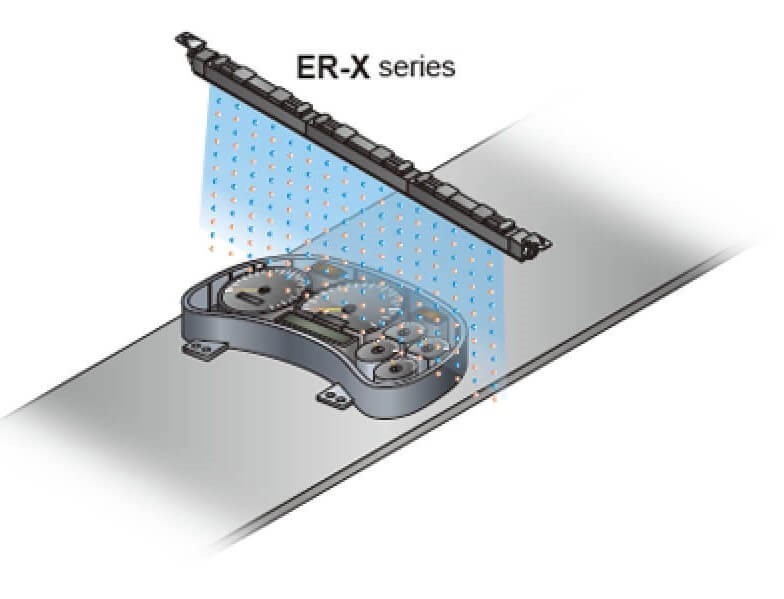

Removing Dust During Instrument Panel Assembly

If dust adheres to an automotive instrument panel, it may cause a quality defect. The ER-X series, which can perform high-speed charge removal without stirring up dust, is ideal for use in preventing contamination and dust adhesion.

Learn more about Panasonic ER-X Series |

Buy Panasonic ER-X Series

Light-Guided Assembly

For Lean Manufacturing

Pick-to-light systems support lean manufacturing initiatives. By reducing the risk of human error in production and assembly processes, pick-to-light is an ideal solution for poka-yoke (error-proofing).

Pick-to-light devices visually guide operators to pick the correct parts, in the right quantities and the proper sequence. This reduces errors and defects and increases productivity by eliminating a common source of wasted time like checking and re-checking instructions.

Automotive Traceability

Technologies for ensuring quality, consistency and compliance

- Track parts with direct part marks, labels and RFID tags

- Verify, read and communicate data throughout the production process

Direct Part Marking

Encode lot numbers, serial numbers and other key information in durable laser markings to track parts throughout their life cycle and across the supply chain. Learn more about Omron Laser Marker MX-Z Series

Fit all the necessary information into concise, streamlined labels for easy track and trace.

Barcode Verification

Ensure the quality of your direct part marks and printed barcodes to prevent no-reads down the line.

Barcode Reading

Employ barcode readers that are designed to withstand the harsh conditions of the automotive factory floor. Learn more about Omron Barcode Reading

RFID

Read and write important data related to part identification and work-in-progress status as part of a

flexible traceability solution. See Omron RFID products

Data Communication

Take advantage of controllers that communicate traceability to the enterprise level without slowing downthe production cycle. See Omron Data Communication

Black Part Detection

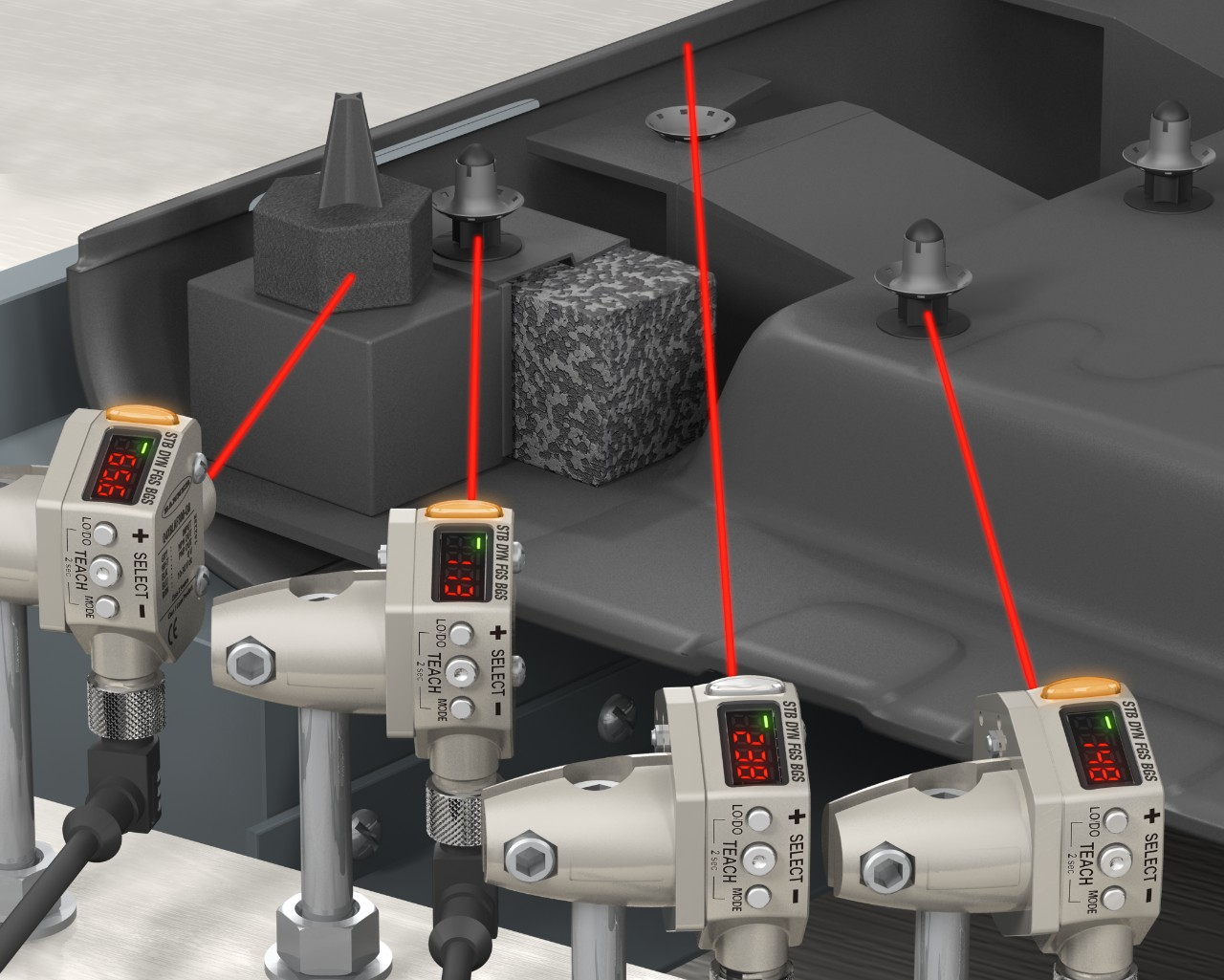

Detecting Black Parts on Black Door Panels

Since door panels are often dark colors such as black or gray, and the foam used to eliminate rattles and provide stiffness is generally black, it can be difficult for standard sensors to differentiate between foam presence and absence due to poor contrast.

Solution: Banner’s Q4X problem-solving triangulation-based laser sensor has no difficulty detecting dark targets on dark backgrounds when there is a height difference. The Q4X provides a reliable sensing solution with best in class excess gain and makes pass/fail judgments based on distance rather than color or reflectivity.

A door panel has four areas where foam should be present, so four Q4X sensors are set up to target these areas and confirm proper assembly by the operator. In this case, three targets are verified, but the fourth is missing. A fail signal is sent to alert the operator that the part needs to be reworked before releasing it from the assembly station.

Along with reliable sensing on challenging targets, the Q4X is extremely durable with a stainless steel housing that resists mechanical impact, vibrations and over tightening. The setup is simple with clear user feedback on the four-digit angled display and set-up buttons located on the back of the Q4X housing.

.png)

.png)