Shop by Category

Loading...

Banner QCM50 Series High-Performance Color Sensor

Reliable color verification, even in challenging color and contrast-based applications

Features

- Reliable color detection across the entire range of the sensor

- Up to 12 colors can be detected with one sensor, which saves inventory costs, enables faster changeover, and increases quality control

- Available in an anti-glare model to reliably detect reflective targets

- Intuitive configuration with integrated LCD display and onboard buttons

- IO-Link communication for remote configuration and monitoring and intensity data visualization

- 270° rotatable M12 Quick Disconnect for simple mounting

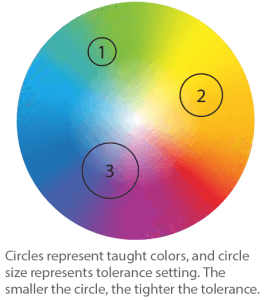

Color Mode: Color Validation Sensor detects and evaluates colors within a specified tolerance. Simply teach a color and select a tolerance from 1-9. Parts that are outside of the tolerance range will not trigger an output.

Color mode is ideal for applications:

- When “bad” colors are not known

- To verify part color falls within a specified tolerance

- Circles represent taught colors, and circle size represents the tolerance setting. The smaller the circle, the tighter the tolerance.

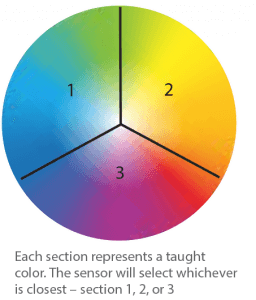

Best Fit Mode: Sorting of Known Colors Sensor always matches the target to the closest of two or more taught colors. To prevent unwanted switching, teaching the background color is recommended.

Best fit mode is ideal for applications:

- When “bad” colors are known

- To differentiate between very similar known colors

- Each Section represents a taught color. The sensor will select whichever is closest–section 1, 2, or 3

Applications

Blister Pack Inspection

Challenge

- A solution is needed that can see through the reflective plastic of the blister pack to verify the presence and color of the tablets

- In pharmaceutical packaging, each pocket of a blister pack must contain a tablet, and each tablet must be the correct color

- For example, a pack of daytime cold medication must contain only daytime tablets (Color A) and not night-time tablets (Color B)

Solution

- Anti-glare models of the QCM50 color sensor see through the shiny packaging to reliably confirm tablet presence and color

- Used in color mode, the sensor verifies the taught color and detects incorrect color tablets

- The QCM50 also differentiates between the tablet color and the background color to detect a missing tablet

- The QCM50 is a cost-effective alternative to a vision solution, and anti-glare models can store up to 7 color settings to verify a wide variety of tablet color combinations

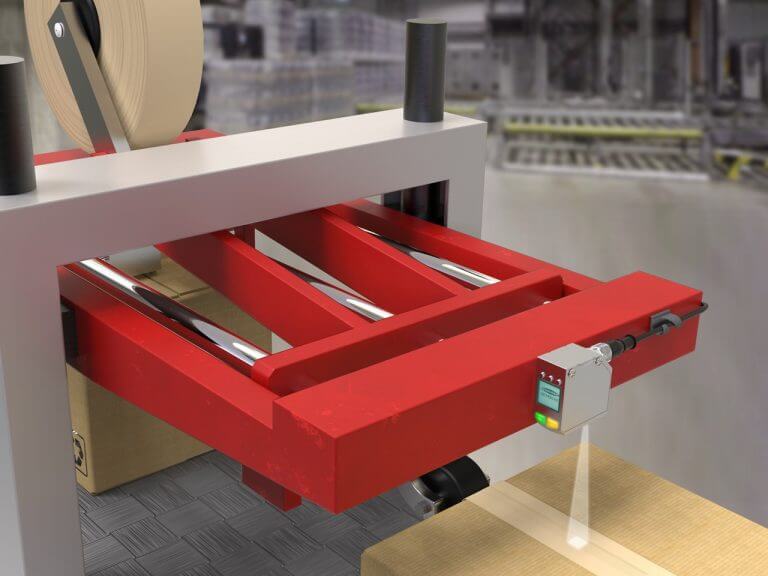

Tape Detection

Challenge

- Mounting several inches above the target is challenging for traditional color sensors

- The limited contrast between the color of the tape and the color of the box can be challenging for traditional sensors to reliably detect

- Before shipment, a sensor must verify that the tape is present to ensure the box will not open and contents will not fall out of the box in transit

Solution

- Long Range models enables flexible mounting up to 150 mm above the application

- The QCM50 color sensor easily differentiates between very similar shades of color to reliably detect brown tape on a brown box

- Used in color mode, the QCM50 sensor validates the taught color (the brown tape) to identify when the tape is missing so the issue can be corrected before shipment

Videos

Resources

BANNER COLOR SENSOR 18-60MM; 3) PNP/NPN

$978.50

Call for lead time*

UOM : EA

BANNER COLOR SENSOR, 18-60MM,1) PNP/NPN

$836.00

Call for lead time*

UOM : EA

BANNER COLOR SENSOR, 18-32MM, 3) PNP/NPN

$978.50

Call for lead time*

UOM : EA

BANNER COLOR SENSOR, 20-150MM,5) PNP/NPN

$1,267.30

Call for lead time*

UOM : EA

BANNER COLOR SENSOR, 20-150MM, 1) PNP/NP

$836.00

Call for lead time*

UOM : EA

BANNER COLOR SENSOR, 10-150MM, 3) PNP/NP

$978.50

Call for lead time*

UOM : EA

.png)

.png)