Shop by Category

Loading...

Fluidsentry - Fluid Power Safety

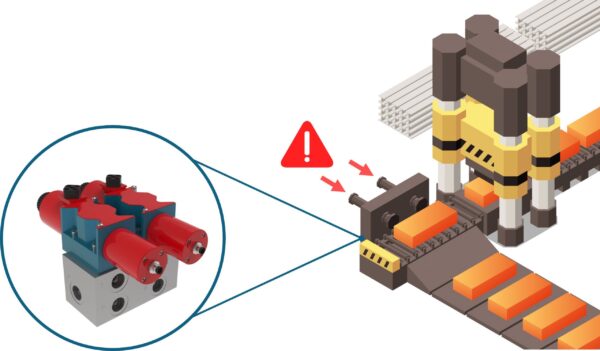

Prevent unpredictable and unexpected motion with safety valve technology

Protection against fluid power hazards must be designed to the same requirements as electrical systems.

Pneumatic and hydraulic systems require the same dual channel architecture and high diagnostic coverage as an electrical system would to achieve functional safety up to Category 4, SIL 3 or PLe.

The most common causes of failure in pneumatic and hydraulic systems are:

- Hydraulic fluid or internal wear generated contamination

- General abrasion

- Heat aging

- Moisture and condensation

- Poor lubrication

Prevent unpredictable and unexpected motion with safety valve technology.

The Highest Level of Fluid Power Safety

- To meet Category 4, ISO 13849-1 states that the safety related parts of the control system (SRP/CS) then change SRP to SRP/CS shall be designed such that a single fault in any SRP does not lead to a loss of safety function…

- ISO 4413 & 4414 detail how functional safety is the advised method to mitigate risks associated with fluid power processes. Whilst fluid power has been a reliable and powerful method to provide motion in industrial processes, when things go wrong, they can be unpredictable.

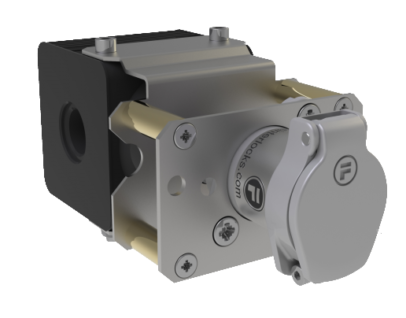

- Fortress Fluidsentry offers a range of market-leading safe pneumatic and hydraulic isolation products designed for Category 4 Performance Level e applications.

Mechanical Bias to Fail-Safe

- The Fortress Fluidsentry range is designed with redundancy in mind for every component.

- ANSI B11.26 states how pneumatic and hydraulic systems shall be designed such that any failure to a system will result in that system moving to a ‘safe state’.

Maximize Efficiency with Operation Zoning

- The fluid power for hydraulic and pneumatic energy often comes from one supply line.

- Isolating the entire supply unnecessarily can be expensive and a huge inefficiency to productivity. Safety valves can be used to zone your supply lines via a control system to vent and exhaust downstream pressure to the local area surrounding the hazard.

- Localised isolation maximises productivity whilst one zone is ‘out of action’ to minimise the effect of downtime.

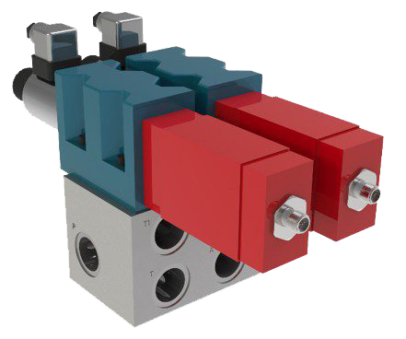

Add-Ons for Every Scenario

- Designed with redundancy on every component.

- Fortress Fluidsentry products use patented technology to ensure pressure is safely exhausted and vented through redundant means in cases where an exhaust channel is blocked.

- The manifold within all Cat. 4 PLe valves have a series ported cross-linked manifolds to provide the additional surety that your are in the safest hands.

Videos

Resources

Like What You See?

Contact our engineering team to determine your ideal Fluidsentry configuration.

.png)

.png)