Shop by Category

Loading...

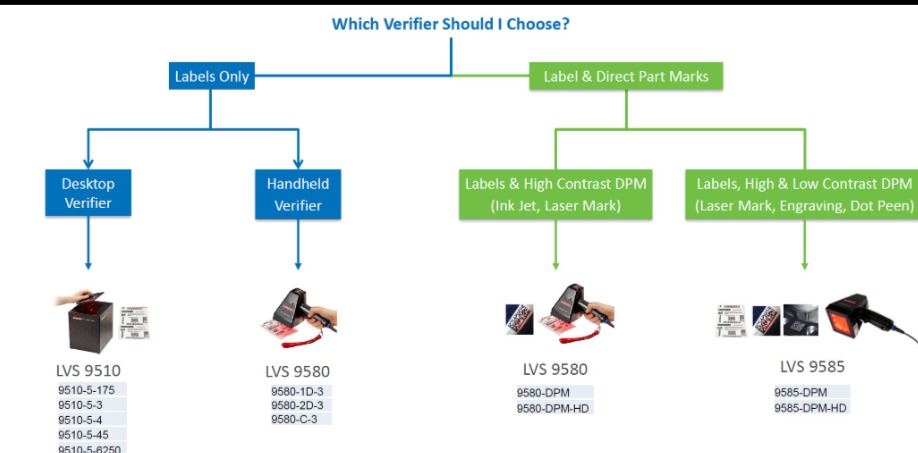

Barcode Verifiers

Verification

- Verification is an objective, precise standardized measurement of the quality of a barcode symbol against a published specification

- Verification is a predictor of how well a code will be able to be read throughout its life cycle

- The Verifier is the calibrated instrument used to objectively measure the barcode quality

Off-Line Verifiers

- Off line Verifiers can be used to measure barcode quality

of a single barcode at a time. Usually on a label or DPM.

- DPM stands for Direct Part Marking where the barcode is

marked onto the part or into the part.

- Some DPM Barcodes use depth for the marking (dot peen,

percussion & some laser marks).

- These are a Low Contrast DPM and require the 30 degree angle lighting , specifically available on the LVS 9585.

LVS-9585 Series

- Stitching feature to grade barcodes larger than the field of view.

- Ideal for multiple line production and warehouse environments.

- Validates printed barcodes to ISO/IEC, GS1, and UDI print quality standards.

- Verifies direct part marks (DPM) to ISO, MIL-STD-130, and GS1 standards.

- High resolution version verifies 2D symbols as small as 2 mil (50 µ) cell size.

- Software upgrade options include Multi-Sector for verification of multiple

barcodes on a label.

- 21 CFR Part 11 compliant-ready.

- Supports 15 languages with the ability to add more.

- Quality data reporting for auditing purposes.

- Includes NIST-Traceable Calibrated Conformance Standard Test Card

for system calibration.

- Optional adjustable mounting stand adapter

.png)

.png)