Shop by Category

Panasonic ER-X Series - Area Pulse Ionizers

Slim, bar type ionizer for wide area coverage of in-line processes, with or without a compressed air source

- Three charge removal modes

- Airless, low-pressure, and high-speed modes are available for expanded application coverage

- High speed, wide area charge removal

- Resolves target movement issues in the presence of compressed air

- Dual head configuration for enhanced charge area and layout expansion

Features

Three charge removal modes

With three different charge removal modes, the ER-X Series is suited to a variety of applications. Modes include "Fast Charge Removal," "Airless," and "Low Pressure". Dual-head configurations support expanded application coverage.

(3).jpg)

Spot type head

The spot type head allows for 0.3 seconds or less charge removal time with pulse AC method.

(1).jpg)

Air supply port for flexible applications

With a internal air tube for air supply, the ER-X Series supports airless and low-pressure charge removal without blowing away tiny work places.

.jpg)

Bar type head

The bar type head, also featuring high and low temperature resistant models, offers a variety of models with a flat discharge surface for easy cleaning.

.jpg)

Ultra-slim head

The ER-X Series features an entirely redesigned discharge needle for an ultra-compact slim head. Combining high-speed charge removal and a maintenance-saving design the ER-X Series is ideal for a variety of applications.

.jpg)

Easy needle replacement

The removable discharge needle unit featuring a set of four needles simplifies maintenance and makes it easy to replace needles as needed.

.jpg)

Dual head configuration

Combine multiple heads in a the new dual configuration controller for simultaneous connection of bar type and spot type heads to improve efficiency.

.jpg)

All-in-one model

.jpg)

Applications

.jpg)

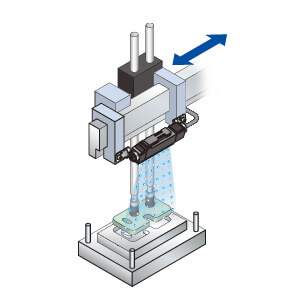

Preventing electrostatic damage during bonding

.jpg)

Removal of static charges on laminate film

.jpg)

Charge removal and dust removal while separating TAB protective film.

.jpg)

Removing dust during instrument panel assembly

.jpg)

High-speed charge removal on a taping machine

.jpg)

Prevention of part feeder clogging

Charge removal of molded plastic components on a conveyor belt

.jpg)

Removing dust during food product cup transport

.jpg)

Airless charge removal of minute components on a conveyor belt

.jpg)

High-speed charge removal on FPCs

.jpg)

Charge removal and dust removal of digital camera cases on a conveyor belt

.jpg)

Preventing adhesion of molded parts to molds

.png)

.png)