Shop by Category

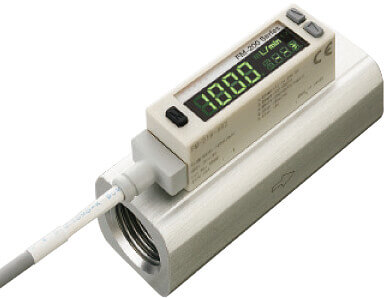

Panasonic FM-200 Series - Digital Flow Sensors

Measures air flow up to 1000 liters/min

- One of the industry's smallest sizes

- Easy to see dual color with sub display

- High precision in miniature size

- Integrated flow rate display

The FM-200 Series is a bi-directional digital flow sensor for use with air or Nitrogen gas. It offers high precision detection in an ultra small package, thanks to the utilization of MEMS technology. The series covers a wide range of flow rates and has a wide range of I/O options standard, such as dual discrete outputs, an analog voltage output, and an external input. Dual digital display: The integrated two-color dual digital display offers quick and easy verification of the sensor's operation, including flow rate, direction, and output condition. Bi-Directional flow detection: The unique sensor chip of the FM-200 allows for flow sensing in both directions. The unit utilizes two temperature sensors, one on each side of a heater element, to determine the heat distribution. This concept provides accurate detection, regardless of flow direction..

Features

Easy-to-see dual color with sub display

The sensor features a dual color digital display, which allows operators to check the status of the sensor operations at a glance

-(1).jpg)

High precision of ±3% F.S.

The sensor features a new rectification mechanism, as well as a Micro Electro Mechanical System (MEMS) technology, which allow the sensor to be mounted on a Si sensor chip (3 x 3.5 mm) and provides an extremely small heat capacity, high precision of ±3% F.S., and high-speed response. The two temperature sensors on either side of the heater detect heat distribution and enable bidirectional detection.

-(1).jpg)

One sensor for both intake and exhaust

A single sensor can detect flows in two directions, making it suitable for a variety of applications

-(1).jpg)

-(1).jpg)

No straight pipes needed

The sensor features a new rectification method which eliminates the need for straight pipes at both the intake and exhaust sides.

-(1).jpg)

Connection

The cover-attached connector enables quick connection.

-(1).jpg)

Flexible installation direction

There are no limits on installation, other than the ability to carryy out bidirectional detection.

Equipped with a wide variety of functions for greater ease of use

- Integrated value reset function

- During integrated mode, external input allows reset of the integrated value.

- Analog voltage output

- 1 to 5 V analog voltage output is incorporated.

- Key lock function

- Key operation can be disabled to prevent mis-operation.

- Rattle prevention function (Response time setting)

- The response time can be set to one of seven steps from 50 ms to approximately 1,500 ms. This prevents rattling from rapid changes in flow or from noise.

- Display rate setting

- The display update period for the digital display can be changed to 250 ms, 500 ms or 1,000 ms in order to eliminate display flickering.

- ECO mode

- After approx. one minute of no operation, sensor will be switched to ECO mode. Backlight will be turned off to reduce power consumption.

Suitable for cost and quality control

The FM-200 series is capable of controlling and managing flows in wide variety of output modes, depending on the required application.

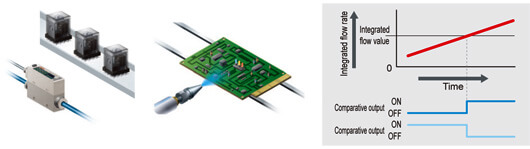

Integrated output mode

When the volume of flow of the gas being measured reaches a set integrated value, output switches ON or OFF.

- Controls N2 charging volumes for electronic components

- Controls air blowing volumes, etc

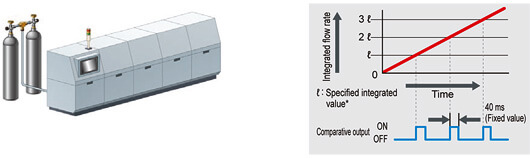

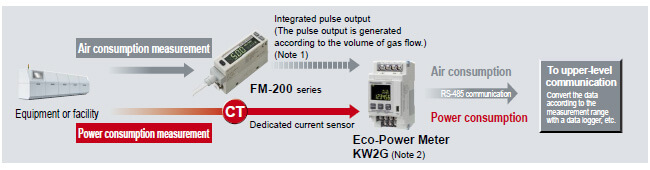

Integrated pulse output mode

The pulse output is generated once at every specified integrated value, allowing the operator to know the amount of air consumed per unit of time with ease.

- Controls N2 purge volumes in reflow furnaces

- Controls overall volumes of air consumed by equipment, etc

Energy-saving and environmentally friendly

The pulse output from the flow sensor can be inputted to the pulse counter of an Eco-Power Meter so that air consumption and power consumption can both be measured simultaneously.

Instant flow rate display

Window comparator mode

This mode is used for setting comparative output to ON or OFF at flow rates within the setting range.

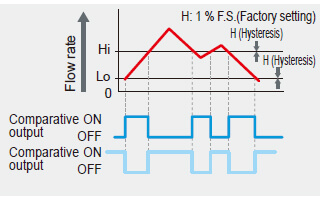

Hysteresis mode

This mode is used for setting comparative output hysteresis to the desired level and for carrying out ON / OFF control.

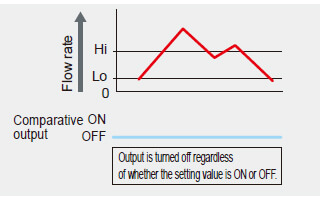

Output OFF mode

Comparative output is forcibly maintained at OFF regardless of the setting value.

Applications

-(1).jpg)

Controlling purge gas and air blowing

-(1).jpg)

Checking seating

-(1).jpg)

Checking suction

.png)

.png)